Reinventing Oyster Farming

At Trátech, we’re on a mission to revolutionize oyster farming with innovative technology that significantly cuts manual labor, combats marine litter, and bolsters farm profitability. Join us in nurturing the blue economy with smart, sustainable solutions.”

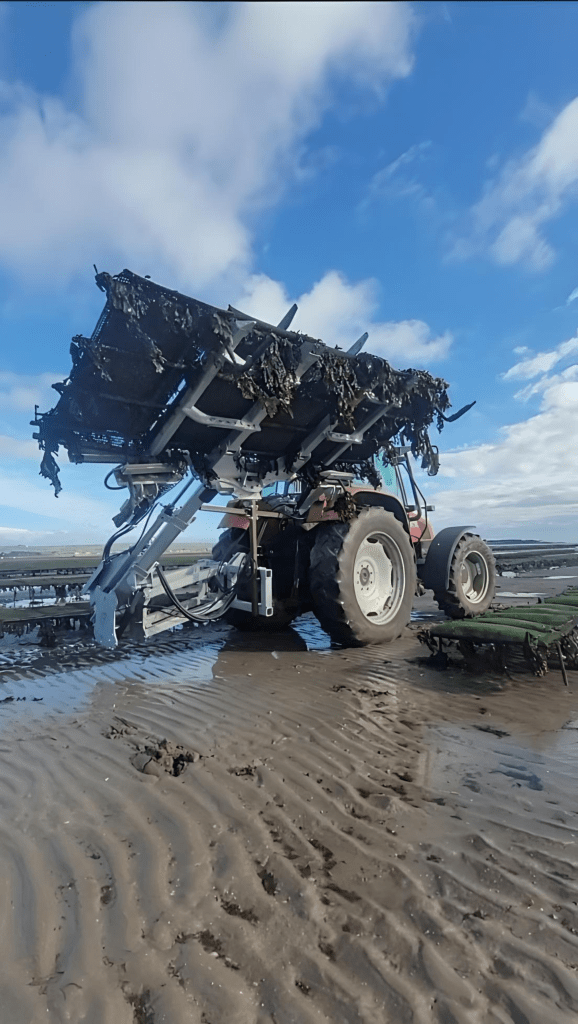

Trestle Turner (Patent Pending)

✓

400 bags per hour

Our machine can turn up to 400 bags per hour.

Giving you more time to do all those other important jobs before the tide comes in.

✓

Front or back

Our machine can be mounted on a front end loader or a 3 point linkage, all that is needed is a change of brackets.

✓

Designed to last

All fabricated components are coated in high quality hot dip zinc galvanize

All fasteners are stainless steel

Hardened 2k paint on all hydraulic cylinders

✓ BIM Trials

Bord Iascaigh Mhara are trialing our machine and are recording oyster quality and growth rates when using the machine

✓

Tractor Requirements

90hp or greater.

One double acting hydraulic spool valve is all that needed.

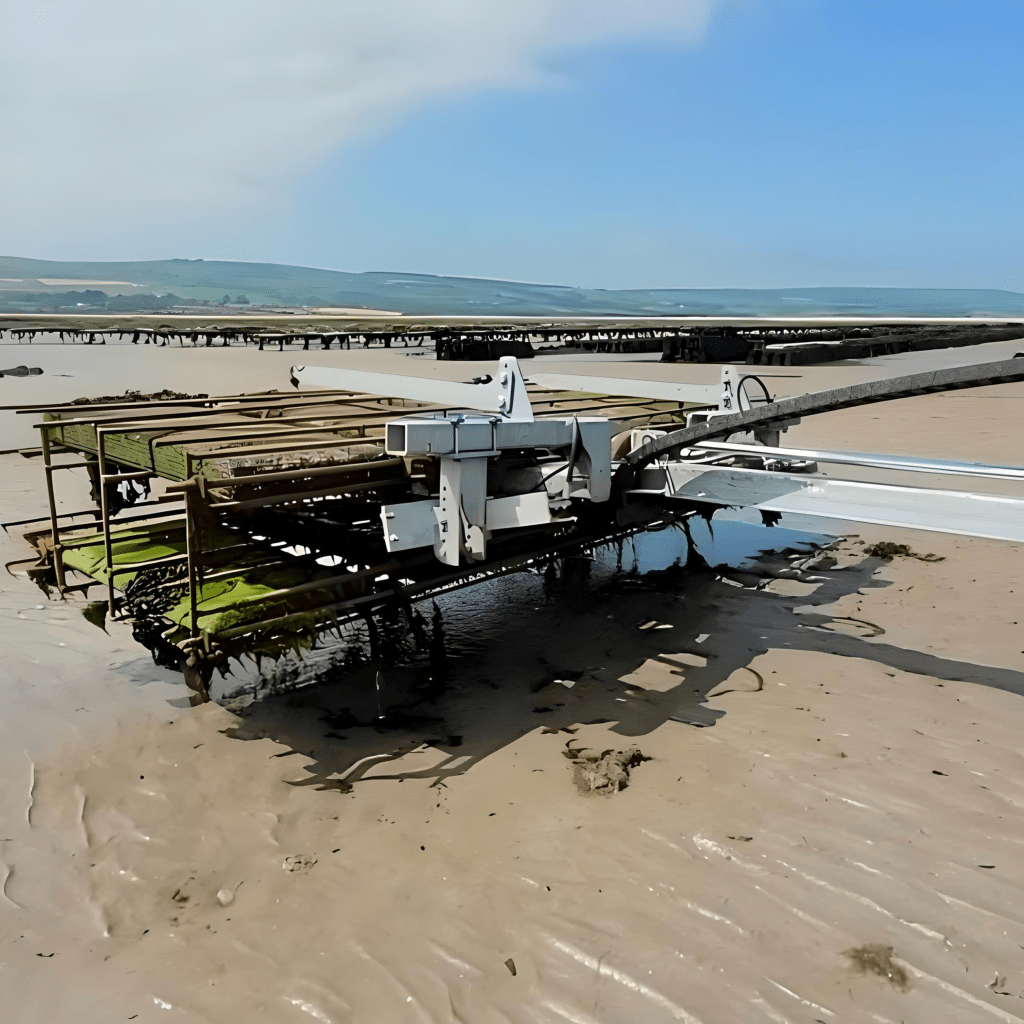

✓ Trestles Lifted

The machine has the added benefit of lifting trestle buried in sand

400 bags per hour

This video shows our machine lifting and turning a trestle table every 45 seconds.

– Lift and turn 80 trestle an hour

– That’s 400 bags per hour on 5 bag trestles

– And 480 bags per hour on 6 bag trestles

– And 800 bags per hour on our Double Layer Basket

Turning Seed and lifting buried trestles

Turning seed

-Perfect for turning seed

-Bags open when fork is upside down during rotation, loosening oysters in bag and allow free movement

-Can lift trestles buried in sand sunk to 15cm

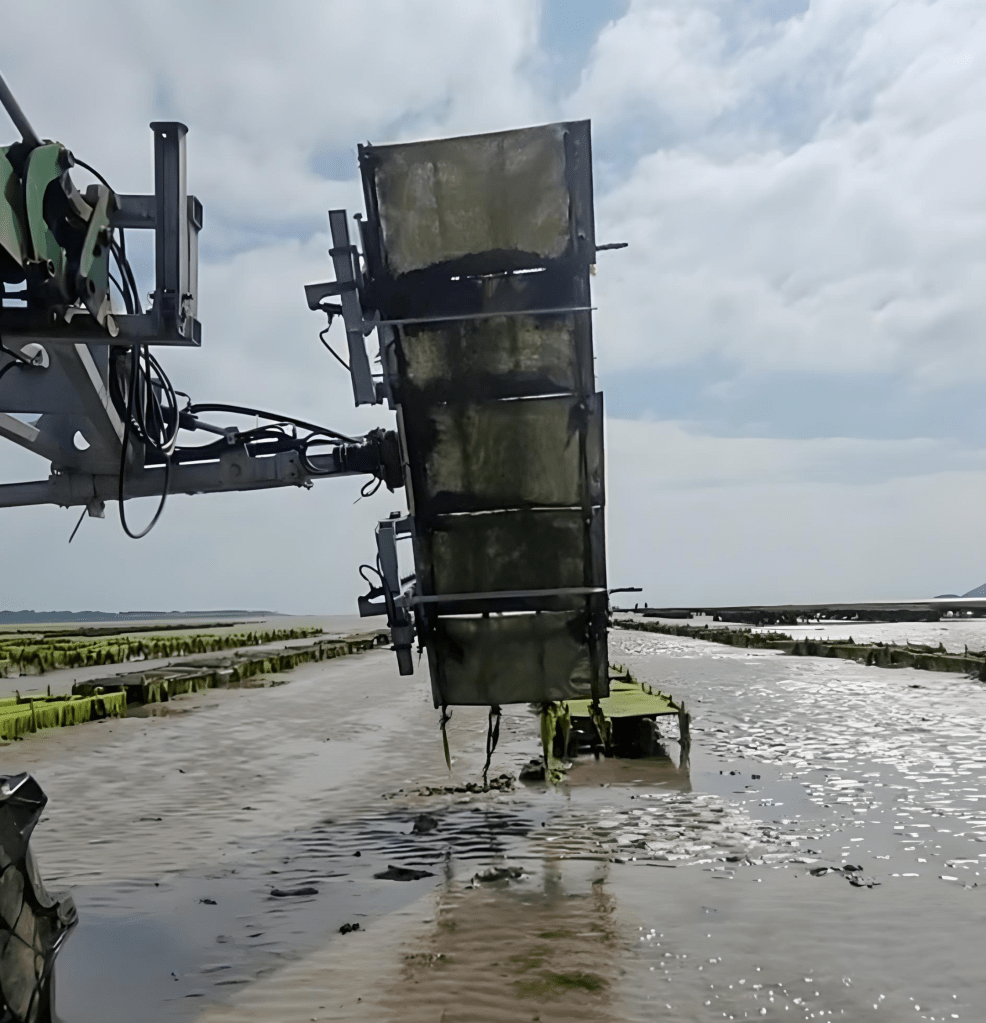

3 point linkage

3 point linkage mounted machine

-Every machine we make can be adapted to either front loader or 3 point linkage, a change of brackets is all that is needed

Locking Bars

✓

Stainless Steel

All parts are made from stainless steel except for rebar bar. This will give them 15+ year lifespan

✓

No rubber

No rubber means they are not only better for the environment but they will not need to be replaced every 3 years

✓

Storm proof

more secure than rubber, less bags will be lost during storms.

The only way a bag can be lost is if it rips.

✓

Quick and Easy

Allows you open and close by simply pulling 4 pins.

Double Layer Basket

✓

Double efficiency

Turn up to 800 bags per hour

✓

More Wind and Wave

Bags are not clamped down, this gives more room in the bags and allows wind and wave action to move oysters

✓

Turn seaweed down

Basket is symmetrical, allows seaweed to be faced down when turning is finished.

✓

Securing Bars

Securing bars can clamp basket onto trestle during storm

About us

The products were designed by Michael French and Colin Harty

Colin is a part time oyster farmer and dairy farmer.

He raises his oysters from seed and sells them when they are half grown.

Colin approached Michael with an idea and asked him to design and make a prototype machine to help Colin keep up with the turning of bags on his farm.

Michael has 10 years experience working as a lead Design Engineer in R&D in both Abbey Machinery (https://www.abbeymachinery.com/) and more recently Tanco Autowrap (https://tanco.global/).

When the prototype worked better than expected, it was decided to apply for a patent on the machine.

Michael is now working full time for TráTech and has set up in his own workshop to manufacture the products.

Before the machine Colin had 300,000 seed every year and struggled to turned it by hand usually only every 6 to 8 weeks.

Now with the machine Colin has increased his seed this year to 1 million and is able to get all the turning done every 4 weeks.

Next year Colin plans to buy 1.5 million seed.

Colin suffers from arthritis is satisfied he can not only stay oyster farming but grow the business now.

Your message has been sent

Let’s chat

Questions, comments or requests?

Feel free to reach out, we’d love to hear from you.

X35 F402

Ahaun

Old Parish

Dungarvan

Co.Waterford

Email:

Michael@TraTech.ie

Michael French 00353 87 639 2345

Colin Harty 00353 87 648 5246